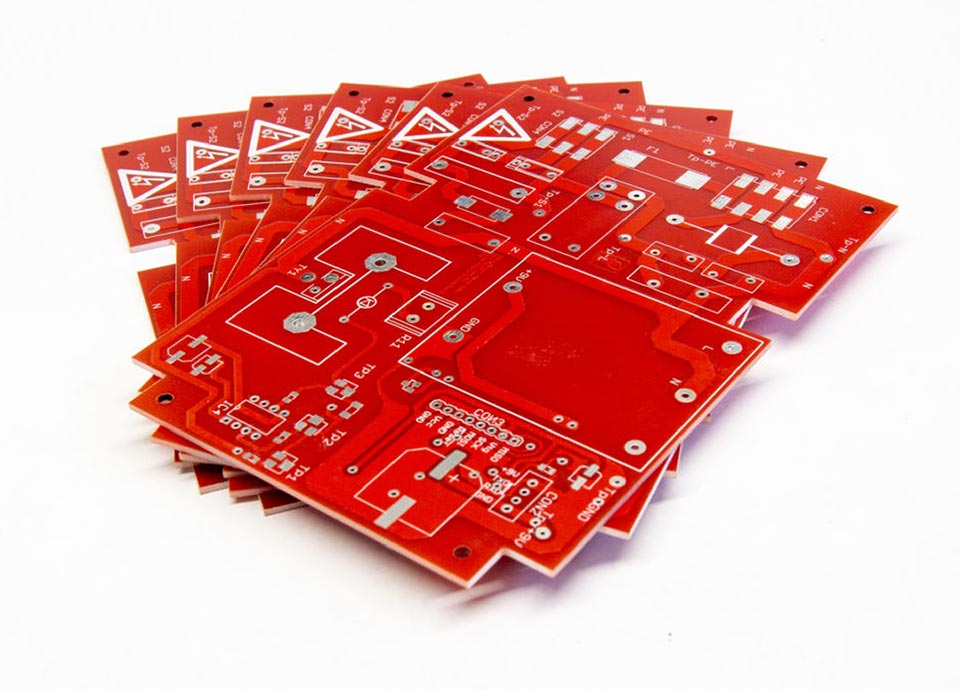

PCB boards

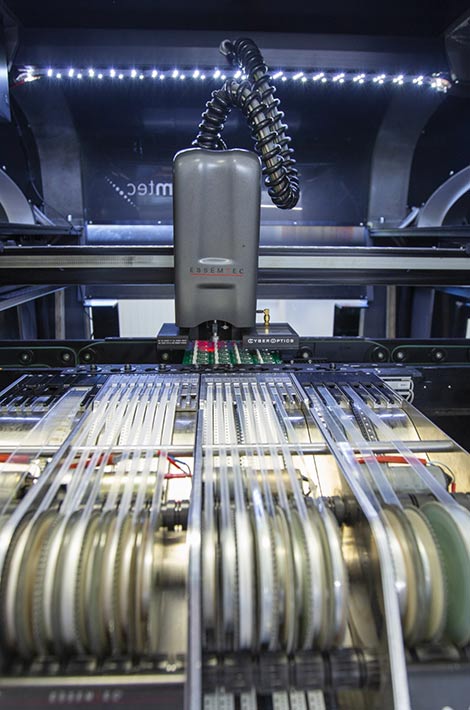

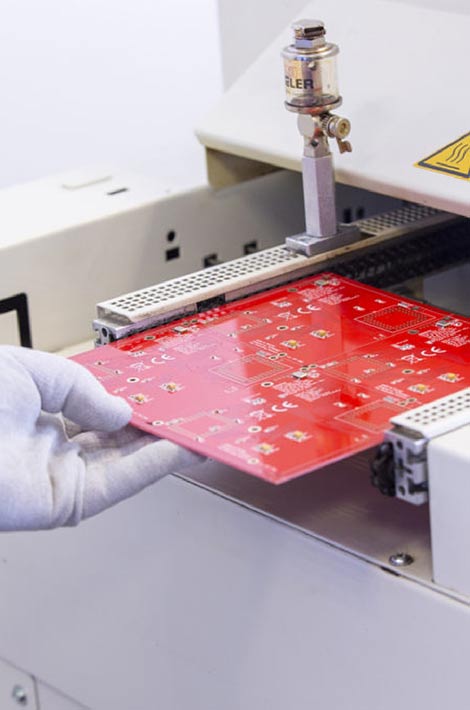

We will take care of ordering the PCBs for you!

We value your time, that’s why we provide consultancy services on selecting and ordering PCBs.

We can offer every kind of PCB available on the market. We complete the order with the delivery of components and providing the production deadline.

We offer our customers both prototype quantities as well as large, cyclic productions. The ordered PCBs can be stored until the next assembly commission.

Fill in your personal information, so that we can respond to you.

Your data is safe with us. We will not share your information or flood you with unnecessary messages. You will only receive the specifics regarding your question.