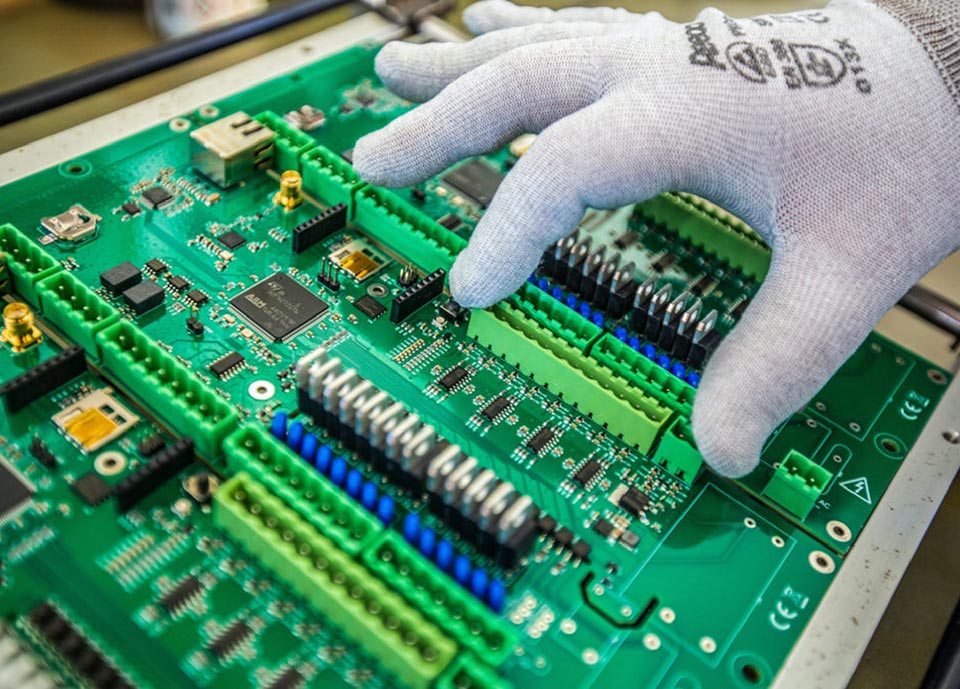

THT assembly

ThT assembly, also called through-hole assembly, is one of the most popular services available from our company. We offer not only the execution of the order itself, but also the preparation of production, the purchase of all the most necessary parts and the PCBs themselves. However, before proceeding, it is worth familiarizing yourself with the details of this type of solution.

Through assembly – what is it?

Through-Hole Technology (THT) contract assembly is a service that is very popular. It involves placing electronic components on a PCB – also known as a Printed Circuit Board (PCB).

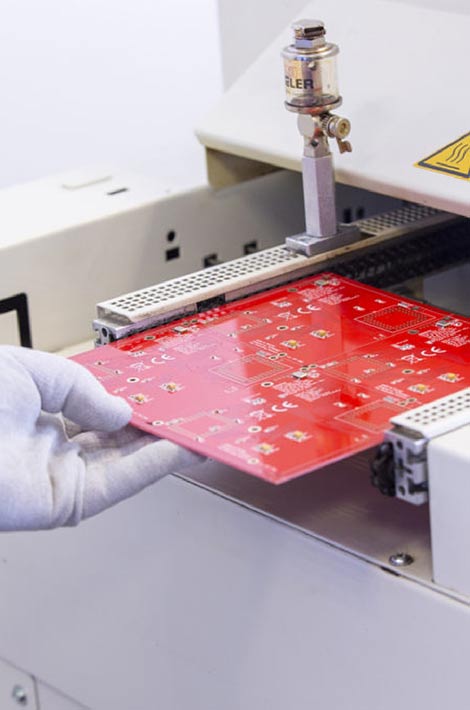

This method is based on putting individual components through special holes that are located in the PCB. They are then soldered to the conductive paths on the other side. THT assembly can be done either manually or mechanically, but due to the minimization of the risk of error and production throughput, the process is fully automated.

ThT soldering is most often used to create various types of components for devices, such as capacitors, transistors or resistors.

How does the process of assembling through-hole components take place?

The THT assembly starts with drilling holes in the PCB. The PCB has special solder fields that lead to the tracks. The holes are adjusted to the position of the components to be installed.

Next, specialists must prepare all the components necessary for the installation. Capacitors, resistors or transistors have special leads, also known as legs, which are threaded through the previously prepared holes in the board.

The board is then prepared for installation.

If necessary, the redundant legs that stick out on the other side are cut off. Once all the components are placed in the dedicated holes, the circuit board is subjected to soldering, which makes the holes fuse with the conducted components, creating permanent connections.

We offer a wide range of soldering services, including the following.

With our company, we also offer the possibility of cleaning the board using a spray or ultrasonic method. The former involves the use of a jet of compressed air or a special spray device to apply a cleaning fluid. This removes any contaminants, residual solder paste or residue left after soldering, eliminating the possibility of corrosion and improving the surface quality. The second method is based on the use of ultrasonic waves, which create microscopic bubbles. As they implode, the shock waves remove any impurities. This method is particularly recommended for parts with complex and unusual shapes.

The final stage involves conducting all the necessary tests to confirm that all components have been correctly and stably installed.

When does the assembly of through-hole components work best?

ThT contract assembly is especially recommended when carrying out slightly smaller productions or creating prototype series. All thanks to its relatively easy fabrication and short lead time. It is also worth remembering that THT components are subject to the possibility of replacement and modification, making them great for use as prototypes. Also, the repair itself is not too complicated.

Soldering THT components is also often used for devices that generate a lot of heat during operation. The aforementioned legs, thanks to their length, perfectly dissipate heat, which is especially useful in components that require cooling. In addition, thanks to soldering, all the components used are mechanically very strong – the connection between the PCB and the rewiring is very strong, which makes THT assembly recommended for applications requiring high mechanical strength.

It is worth remembering that THT assembly takes up more space on the board than SMT (Surface-Mount Technology) application, so it will work better for projects where small size is not a key factor.

If, however, you want the smallest possible device size, then SMT assembly is recommended, which allows components to be placed on both sides of the board, so circuits with higher density still meet the requirement for miniaturization.

Soldering of THT components – EMS Elektronix

Our company has been offering its customers the possibility of THT assembly for years. Our modern machinery and the assistance of qualified specialists are a guarantee of the highest quality. In addition to ordering all the necessary components, we will also advise on the design itself and matching the best components. We also undertake the assembly of non-standard components.

Fill in your personal information, so that we can respond to you.

Your data is safe with us. We will not share your information or flood you with unnecessary messages. You will only receive the specifics regarding your question.