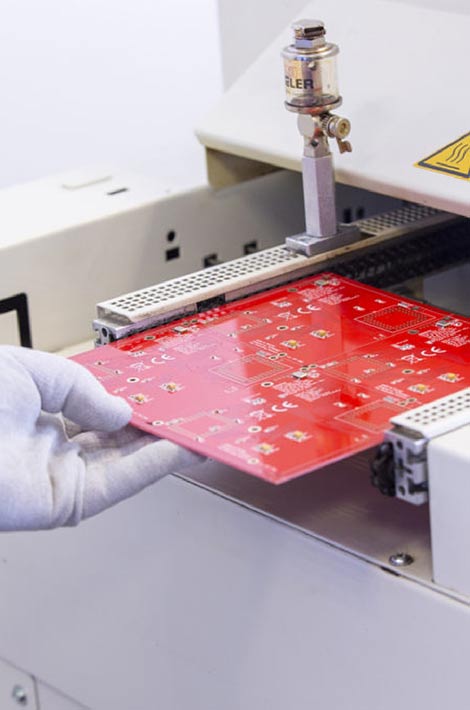

Get to know our machine park

We work with the latest technology and machinery. All this in order to provide you with products of the highest quality.

What can you find in our machine park?

We work on such machines as:

- automatic machines for placement of SMD components,

- automatic stencil printer for solder paste application,

- automatic quality control system (AOI),

- semi-automatic Teach-IN assembly manipulators

- oven for reflow soldering of SMD and BGA components,

- manual stencil printer for prototyping boards,

- ultrasonic cleaner,

- vacuum dispenser for solder paste and glue,

- stations for supplementary, manual assembly of through-hole elements,

- control and measurement station.

Pierwsza linia montażowa SMD

Główna linia montażowa obsługuje duże partie produkcyjne.

Automat JUKI KE1080L zapewnia sprawny montaż z prędkością 20tys elementów na godzinę.

Może pracować nieprzerwanie w cyklu trzyzmianowym 24h na dobę.

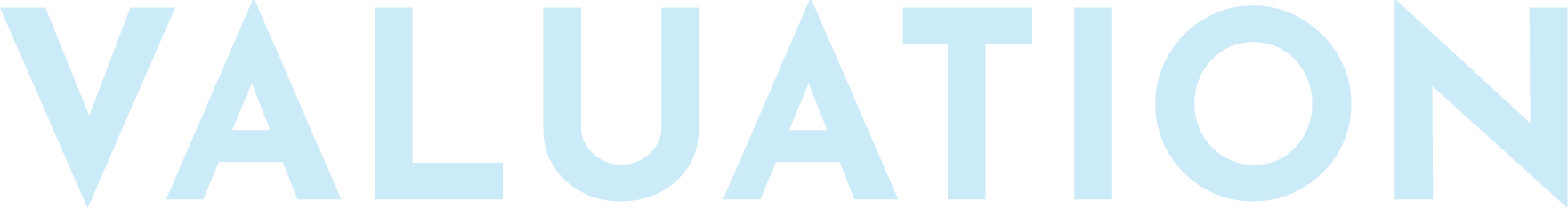

Druga linia montażowa SMD

Linia na podbudowie maszyn Essemtec obsługuje małe partie produkcyjne i prototypowe.

Największym atutem jest łatwość przezbrojenia automatu i uruchomienia nowego zlecenia.

Zapewnia montaż elementów od 3tys do 4tys na godzinę.