Our services

All our clients are guaranteed to have their ideas brought to life and attract new customers with certainty

We keep in touch with you at every stage of the project.

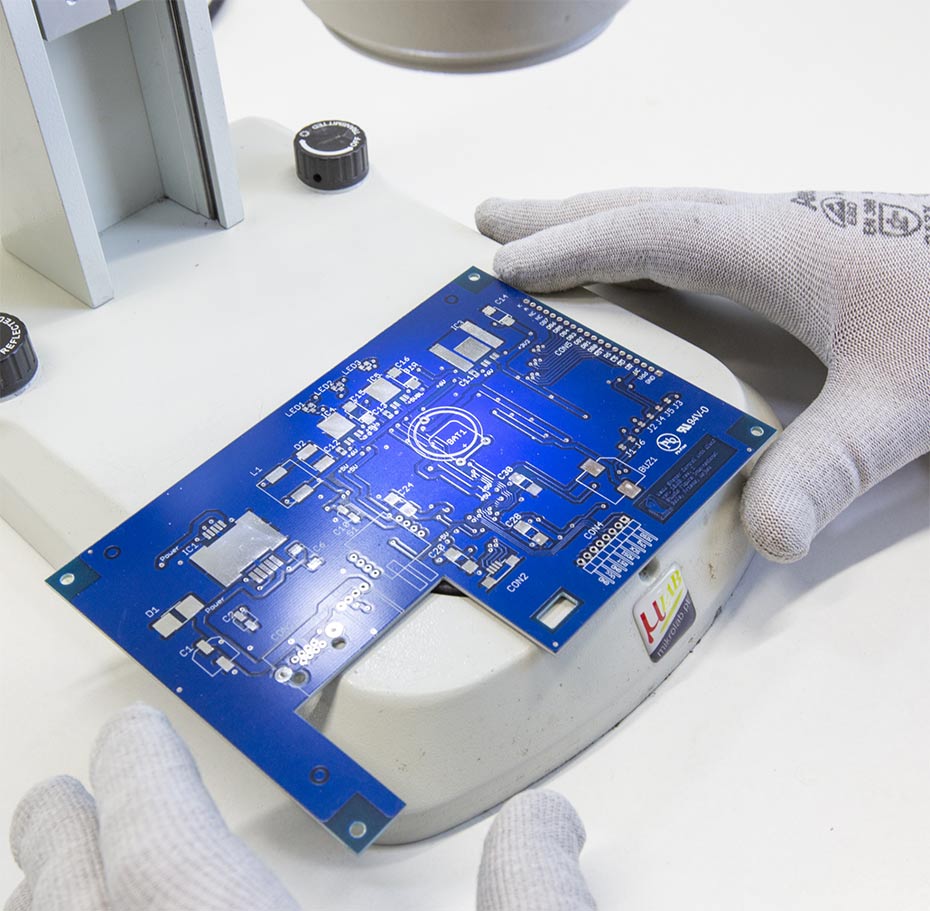

Before starting the production a pilot batch will be sent for Your approval. Only after your acceptance do we begin the production process.

You gain control of every stage of production to ensure that the final product meets your expectations at a 100%.

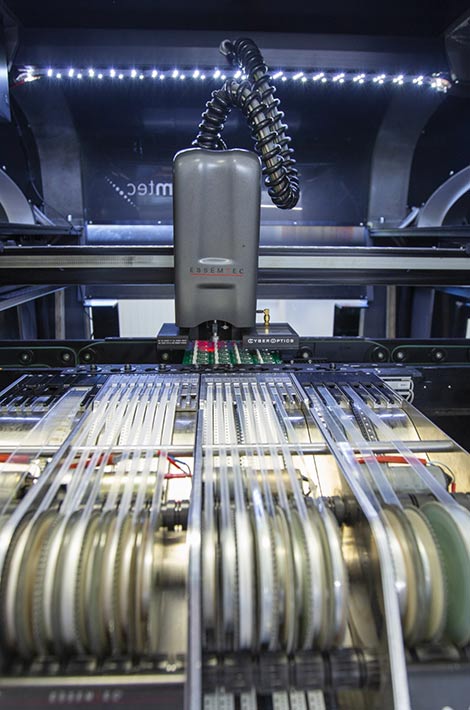

Care and assistance during production

Our flexibility allows for changes during the production cycle. Each stage of production is carried out with due diligence in order to protect the customer from huge losses caused by design errors.

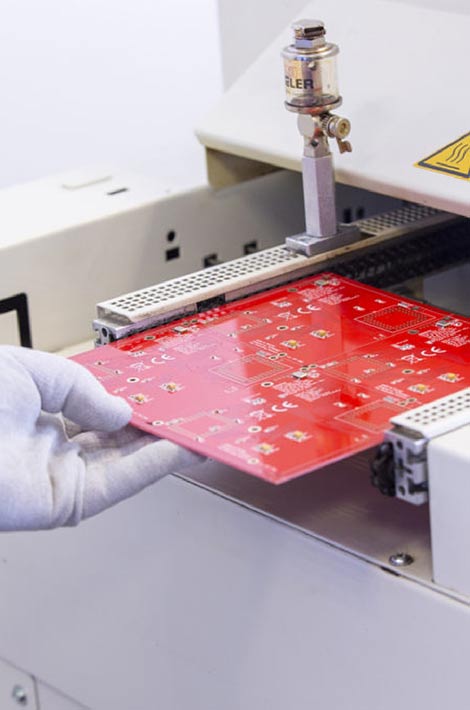

Prototype batch

Before production, we will send you a prototype batch for checking. We start production only after approval. So you gain the ability to react at every stage and be sure that you will receive a product that meets your expectations in 100%.

We gained the trust of companies in multiple branches:

automotive

automotive

fitness

fitness

mining

mining

telecommunications

telecommunications

energetics

energetics

information technology

information technology

household appliances

household appliances

universities and scientific institutions

universities and scientific institutions

medical

medical

Footer

OFFER

MENU

Get it up and running. Let's do something together.

Prepare project documentation in an electronic version. We can't wait to see it! It is bound to be an exciting collaboration.

Ready? Click the button below.

EMS ELEKTRONIX

MENU

SERVICES

ADRESS

20-151 Lublin

© Copyright 2024 EMS Elektronix.

projekt i wykonanie strony internetowej: Miasto Stron