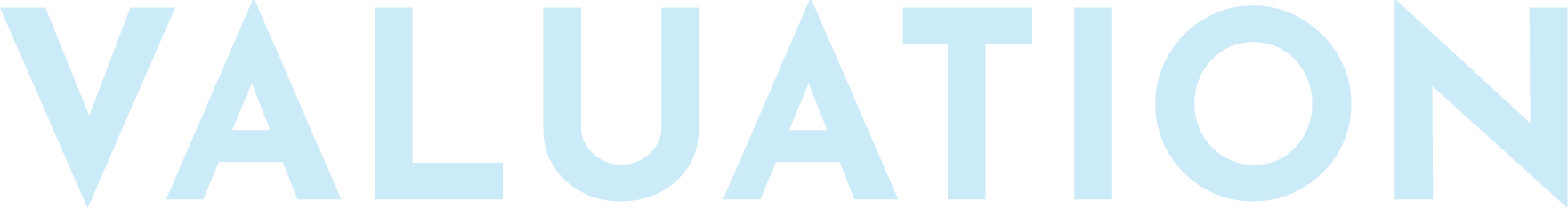

JUKI KE 1080L – an automatic SMD placement machine has joined our machine park.

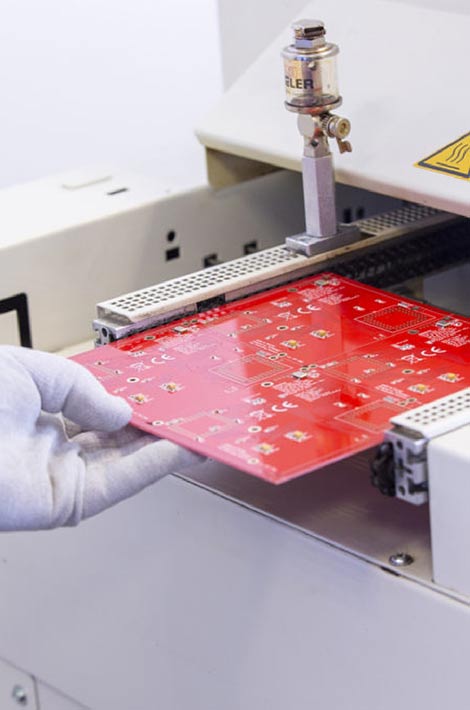

The purchase of new equipment will allows us to perform EMS services faster and with better precision.

The undoubted advantage of the JUKI KE 1080L is fast and accurate assembly of small components, as well as ability to work with non-standard parts. The new technology allows for a precise installing of components in 0402 housings. The machine is characterized by its efficiency, with 17 000 elements produced per hour.

It has a four-nozzle head with a rated IPC9850 speed of 15,500 CP, and it uses a three-color advanced vision system with blue, green and red LEDs to accurately place small ICs, connectors and non-standard shaped components.